Kaizen and Our Future

What is Kaizen?

Kaizen is a practice or process that we have decided to implement here at Osage. The word originates from Japan and translates into “change for the better” or “continuous improvement.”Kai = Change

Zen = Good

• Good processes bring good results

• Aims to eliminate waste

• Generating total quality management

• Small improvements over time turn into large results

• Go see for yourself to grasp the current situation

• Speak with data, manage by facts

• Take action to contain and correct root causes of problems

• Work as a team

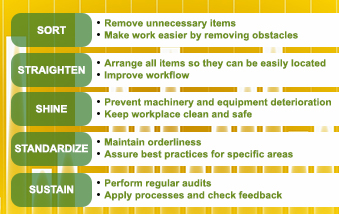

5 S

• Make work easier by eliminating obstacles.

• Reduce chances of being disturbed with unnecessary items.

• Prevent accumulation of unnecessary items.

• Evaluate necessary items with regard to cost or other factors.

• Remove all parts or tools that are not in use.

• Segregate unwanted material from the workplace.

• Need fully skilled supervisor for checking on regular basis.

• Don't put unnecessary items at the workplace & define a red-tagged area to keep those unnecessary items.

• Waste removal.

• Prevent loss and waste of time by arranging work station in such a way that all tooling / equipment is in close proximity

• Make it easy to find and pick up necessary items

• Ensure first-come-first-served basis

• Make workflow smooth and easy

• All of the above work should be done on regular basis

• Use cleaning as inspection

• Prevent machinery and equipment deterioration

• Keep workplace safe and easy to work

• Keep workplace clean and pleasing to work in

• When in place, anyone not familiar to the environment must be able to detect any problems within 50 feet in 5 seconds.

• Maintain high standards and workplace organization at all times.

• Maintain orderliness. Maintain everything in order and according to its standard.

• Everything in its right place.

• Every process has a standard.

• Also translates as "do without being told"

• Perform regular audits

• Training and Discipline

• Training is goal oriented process. Its resulting feedback is necessary monthly

Saftey

At Osage, our top priority is safety. A safe environment is everyone’s responsibility. We have implemented several changes that help keep both our employees and our environment safer. Part of that safety process incorporated the use of the 5 S.

By working together and using Kaizen principles, we have made Osage a better place for our employees, and provided increased quality to our customers.

Bureau of Labor Statistics 2014

• Slips, trips and falls: 818• Injuries by people or animals: 765 (409 of these were homicides)

• Contact with objects and equipment: 715

• Exposure to harmful substances or environments: 390

• Other events or exposures: 149

• Each one of these deaths was 100% preventable.

Occupational Injuries, 4,821 people – more than 13 per day – died while doing their jobs. That is the highest in 7 years.

National Safety Council

OSHA

Community

Creating Jobs. Improving lives. Reducing Landfill. Supporting charities. Getting involved in government.• Go see for yourself to grasp the current situation

• Speak with data, manage by facts

• Take action to contain and correct root causes of problems

• Work as a team

• Kaizen is everybody’s business

Our Future

We are excited to announce that we are currently in the process of expanding and improving on our full service recycling programs. This will help us better serve both our suppliers and our customers.

Blending.

By adding blending silos, we will further be able to meet our customer’s specific need for recyclable product. After all of the testing at our lab, we then will comprise a ratio or blend of certain regrinds that we have recycled in house and fit their needs to come up with a specific product.

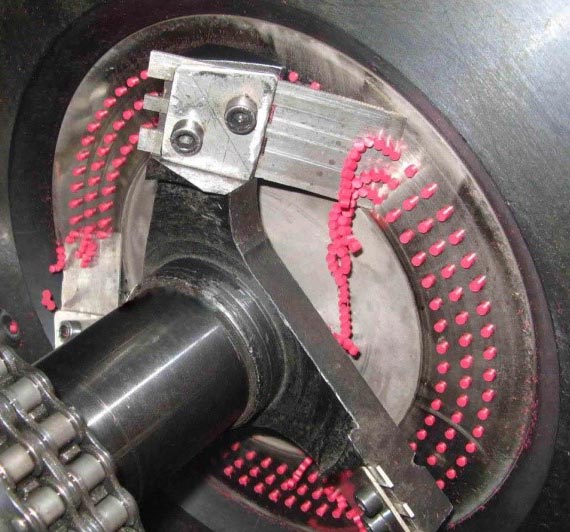

Pelletizing

As the newly formed material exits the extruder, it will then enter a pelletizer. This will turn our liquid plastic into a pellet. This pellet or resin will be even smaller than our regrind. This will give our customer and even better product that is more customizable.

Extruding

After the blend is made it will be re-tested in our lab for quality control. The next process is extrusion. This will take our new blend and infuse the different regrinds together to form one single product. Through the extrusion process, we can also eliminate any foreign material, for a 100% pure recycled product..

Densifying

Another service we are looking to add for our customers is densifying. This can turn some forms of plastics back into re-usable pellets. Think of plastic bags you get at the grocery store. Thin, flimsy, and stretch easily. These cannot be processed like hard plastic. That’s where the densification process comes into play.